As a critical complement to lithium-ion batteries, sodium-ion batteries (SIBs) are accelerating their commercialization in large-scale energy storage and specific power applications, leveraging advantages such as abundant sodium resources and excellent low-temperature performance.

However, behind the rapid expansion of the sodium-ion battery industry, the selection and optimization of anode materials remain a key technical bottleneck restricting the performance enhancement of SIBs.

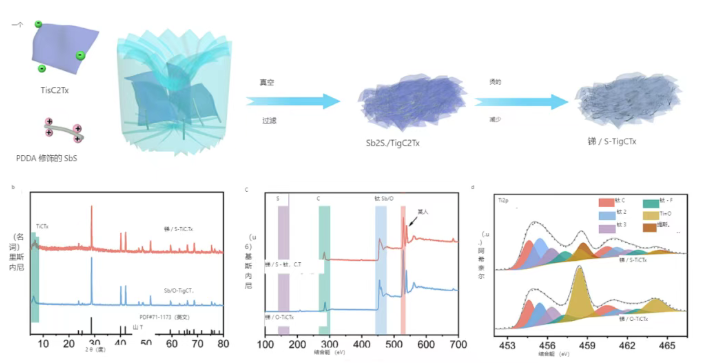

Recently, the paper titled Reinforcement Mechanism of Functional Sulfur-Doped Ti₃C₂Tₓ Confined Antimony Anodes for High-Performance Sodium-Ion Batteries, authored by Mr. Yang Jian and with industrialization guidance provided by Mr. Yan Jiachun, Chairman of CNAE, was officially published. It delivers a groundbreaking innovation for sodium-ion battery anode technology.

1. CNAE’s Focus on the Multi-Level Industry-Academia-Research (IAR) Ecosystem

As a pioneer in the industrialization of sodium-ion batteries, China Sodium-Ion Battery Group (CNAE) originated from the laboratory at the Cambridgeshire Innovation Centre. Rooted in the cutting-edge technological perspective of world-class universities, CNAE highly values the IAR collaborative innovation model and has established a multi-level IAR collaborative innovation network.

Through in-depth cooperation with top international research institutions and key domestic universities, CNAE has achieved the rapid transformation of theoretical research into industrial applications:

Focusing on the interface regulation of sodium-ion battery materials and low-temperature performance optimization, it has expanded the operating temperature range of SIBs to -45℃~80℃. The capacity retention rate exceeds 90% at -20℃, and the 5C fast-charging performance enables charging to 80% in 15 minutes, significantly extending the boundaries of safe power consumption.

Its comprehensive R&D and production strength has consistently ranked among the global Top 3 in the sodium-ion battery industry.

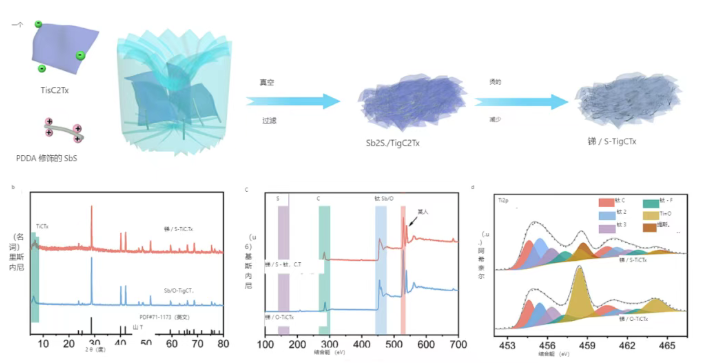

2. Joint IAR Project: Sulfur-Doped Antimony Anode Mechanism Yields Remarkable Results

Recently, the IAR project of Jiangxi Normal University, in which Mr. Yan Jiachun, Chairman of CNAE (co-author of the paper, ranked third), participated deeply, has achieved a breakthrough.

The research achievement presented in the paper Reinforcement Mechanism of Functional Sulfur-Doped Ti₃C₂Tₓ Confined Antimony Anodes for High-Performance Sodium-Ion Batteries—authored by Mr. Yang Jian and guided by Chairman Yan Jiachun in industrialization—has opened up a new path for sodium-ion battery anode technology.

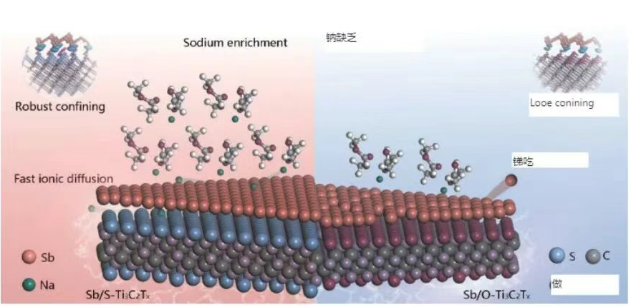

The interface bonding mechanism of sulfur-doped MXene in this technology complements CNAE’s existing "Interface-Electrolyte Synergistic Stabilization Technology", and is expected to solve the volume expansion challenge of high-capacity antimony anodes.

Currently, mainstream sodium-ion battery anode materials face three core challenges:

Difficulty in balancing energy density and rate performance

Commercial graphite anodes (a common lithium-ion battery material) have a small interlayer spacing. Sodium ions are 30% "larger" than lithium ions, making it hard for sodium ions to intercalate, leading to a sharp drop in energy storage capacity—the sodium storage capacity per unit volume is less than 1/10 of the lithium storage capacity.

Poor cycle stability caused by repeated charging and discharging

Alloy materials such as tin and antimony can accommodate more sodium ions (with a 18-fold capacity increase), but they undergo severe volume expansion of over 200% during charging and shrink back to their original state during discharging. Repeated "expansion-contraction" causes material fragmentation and drastically shortens battery lifespan.

Room for improvement in comprehensive performance

Current mainstream hard carbon materials experience a 70% capacity plummet during fast charging (10-minute quick charge);

Moreover, their loose molecular structure results in a per-unit-volume energy storage capacity that is only 80% of that of lithium-ion batteries, leading to reduced battery endurance.

Therefore, the research and innovation of sodium-ion battery anode materials have always been a major challenge for the industry.

3. Synergy of Technological Innovation: Complementary Evolution of Sulfur-Doped Antimony Anodes and CNAE’s Technology Matrix

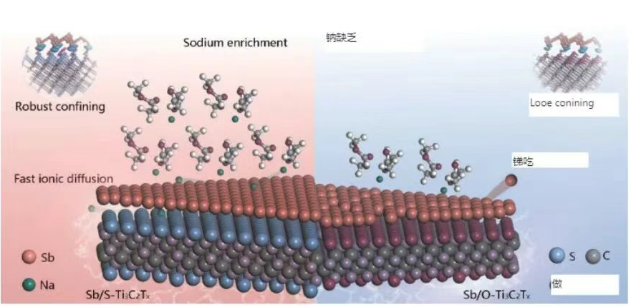

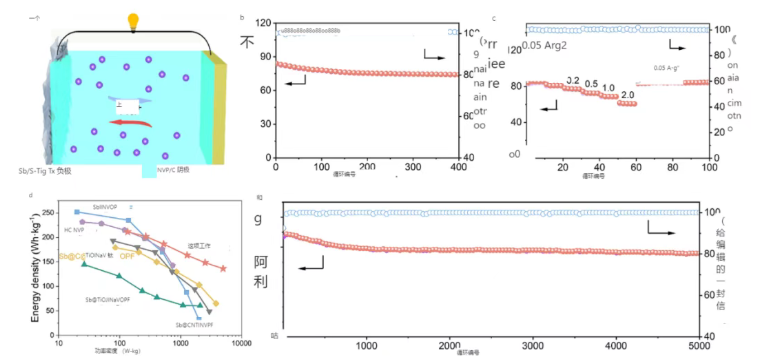

The greatest innovative significance of this paper lies in the following:The core breakthrough of the sulfur-doped antimony anode lies in overcoming the technical barrier to comprehensive performance improvement through the dual mechanisms of "chemical bond anchoring and spatial confinement", which can form multi-dimensional synergy with CNAE’s existing technology routes:

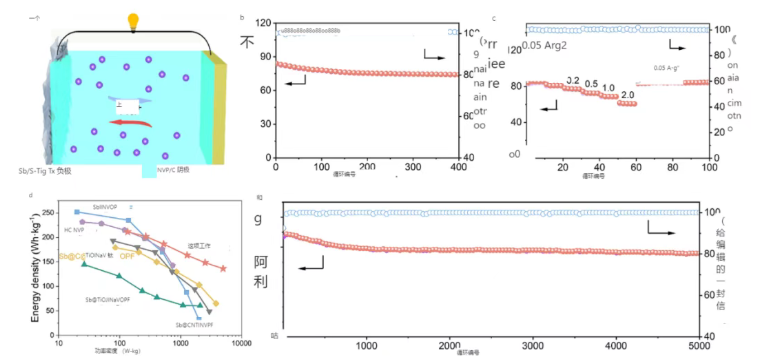

(1) Dual Enhancement of Battery Performance: Higher Energy Storage & Better Low-Temperature Resistance

Significant improvement in energy storage capacity

Compared with traditional graphite materials, the sulfur-doped antimony anode increases the energy storage capacity by 79% per unit weight, enabling the energy density of CNAE’s layered oxide system batteries to jump from the current 167Wh/kg to the 220Wh/kg level.

In other words, the driving range of sodium-ion battery-powered electric vehicles can be extended from 167 km to 220 km, approaching the level of mainstream lithium iron phosphate batteries.

Further enhancement of low-temperature performance

MXene materials form an "anti-freezing protective film" (SEI film) on the anode surface. Combined with CNAE’s specially formulated antifreeze electrolyte, the battery’s capacity retention rate exceeds 90% at -40℃. This further improves the capacity retention rate at -40℃ from 85% to over 90%, ensuring the normal operation of sodium-ion batteries even in the extremely cold environments of Northeast China.

(2) Upgraded Battery Interface: Longer Lifespan & Faster Charging

Breakthrough in the stability of the battery "protective film"

The protective film (SEI film) formed by sulfur doping is 60% thinner than traditional films. It forms a coupling effect with CNAE’s "Three-Resistance Technology". Experiments have shown that it only thickens by 1.8 nanometers after 300 charge-discharge cycles, curbing the dangerous signal of "battery expansion" and significantly extending battery lifespan.

Steady improvement in charging speed

Sulfur atoms act as sodium-philic sites, constructing "sodium-ion exclusive channels" inside the battery, reducing charging resistance by 40%. Combined with CNAE’s 3D electrode structure, it accelerates ion transport and further enhances fast-charging performance.

(3) Dual Explosion-Proof Protection: Higher Safety & Stability

Thermal conductive fire suppression system

MXene materials act like "firefighters" inside the battery—their thermal conductivity is 5 times that of copper. Combined with the SEI film, they form an internal fire barrier, increasing the battery’s heat resistance temperature from 180℃ to 250℃ and passing the world’s most stringent energy storage safety certifications.

Accelerating the R&D of anode-free sodium metal batteries

If the research results of this paper are applied to new sodium-ion battery technologies, the "expansion rate" of antimony anodes can be reduced to 25% of the original level,

providing a material foundation for CNAE to develop thinner and lighter anode-free sodium metal batteries.

Conclusion

As emphasized by Mr. Yan Jiachun, Chairman of China Sodium-Ion Battery Group—"Cost is the unchanging underlying logic of sodium-ion batteries".

The emergence of sulfur-doped antimony anode technology provides a key fulcrum for CNAE to lead the transformation of the sodium-ion battery industry.

From the perspective of the significance of this paper’s publication, adhering to the accelerated mechanism of IAR integration is of long-term and strategic importance for enhancing CNAE’s R&D and production capabilities. By sticking to the path of "process innovation, production acceleration, and cost reduction", CNAE will continuously lower the marginal cost of sodium-ion battery production and expand the theoretical advantages of sodium-ion batteries in terms of cost-effectiveness and quality.

As a global Top 3 sodium-ion battery enterprise, CNAE will continuously deliver innovative achievements, driving sodium-ion batteries to become a new engine for green energy transformation, and ushering in a new strategic cycle in the trillion-level energy storage market and the electric mobility market benefiting all people.